Overhead monorail machines

Type CAPSOR® and LINEXA

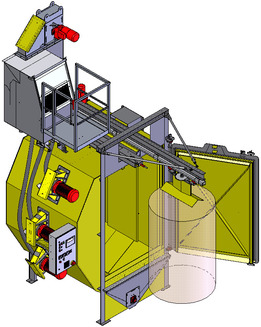

Type CAPSOR®: Infeed procedure

For all-round, automatic shotblasting of individual workpieces or those attached to a transport rack in batch processing by means of blast wheel technology. Attachment occurs on an overhead monorail system with carriage or lifting gear. The cluster of workpieces rotates and oscillates in the blast area during the blasting process.

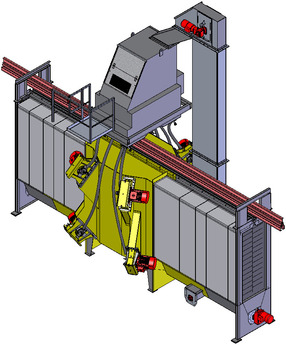

Type LINEXA: Run-through process

👆 Experience the LINEXA in action! With 3 attachment and suspension robots, it impresses with great automation!

👇 Even without automation with up to 16 R410 blast turbines, the overhead conveyor blast machine can achieve remarkable results! The machine shown below is equipped with 8 turbines. It blasts reliably at 0.5 - 2 m/min and can be easily integrated into a coating line:

For shotblasting of profile constructions and other components and also for sweeping galvanized workpieces in continuous operation by means of blast wheel technology.

Attachment occurs on crossbars of a manual overhead rail system, a Power & Free conveyor system or a circle monorail conveyor system, for heavy loads also with electric hoists.